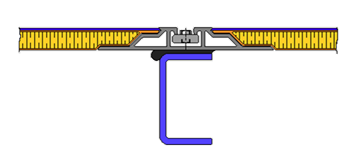

Typical installation showing panel joint with extruded aluminum rail for floor-mounting seats.

Lightweight, VARTM Plank Flooring System for van conversions, cutaway, shuttle, & medium-duty buses, and Light Rail Transit applications

RMC's newest composite flooring product consists of three, modular, interlocking planks. Each plank is manufactured using vacuum-assisted, resin transfer molding technology, encapsulating a core of end-grain balsa or ultra-lite, foam-filled, phenolic-infused craft paper honeycomb, creating a very adaptable, lightweight product of exceptional strength and durability.

Ideal for body-on-chassis vehicles and medium-to-heavy duty urban transit buses with or without integral structures, plank kits are supplied cut to shape, ready to install or as bare lineals to be processed by the OEM. Options include: extruded aluminum seat rails; variable geometry for 98” and 102” vehicles; cut-to-shape edges to clear side posts, wheel chair ramps, step wells, wheel housings; select floor coverings can be factory-bonded or applied after installation.

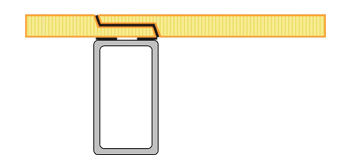

Plank floor, no seat rail

The 3-plank system offers the ultimate in design flexibility.

With no tooling cost for ¾” (19mm) standard format, RMC's pultruded composite flooring speeds assembly, reduces labour, eliminates leaks, and completely eliminates piece-built plywood, composite, or phenolic floor assemblies. 31% lighter than ACQ plywood and stiffer - allowing greater un-reinforced spans – RMC’s planks are supplied compliant to FMVSS 302, or to Docket 90A ASTM E-119, and are impervious to rot, mildew, or delamination.